DuraCoat Durability

One of the most common questions we are asked is, “Is DuraCoat really durable?”

The short answer is, “Yes, it is.” The durability of DuraCoat is the reason that we began offering DuraCoat finishes in the first place. It was through my own experience that I became so impressed with this finish that I became interested in doing DuraCoat for others.

Instead of trying to describe the durability, or using some kind of test that may or may not have any real meaning for a real world user, we will take a look at a couple of weapons to see how their DuraCoat finishes have held up.

Daily Carry

The first is an XD® Pistol. I purchased this pistol used but with very little wear about 5 1/2 years ago. At the time, I was doing a lot of explosives work and spending a lot of time drilling rock for blasting. I constantly had abrasive rock dust on everything, and within a few months there was almost no black finish left on the slide. People asked why my pistol looked so bad when I did finishes for other people, so I decided to do some experimenting with it. I coated it black with artwork on the frame, and someone was wanting to see an example of a tribal design at the time, so I did that on the slide. For five years I have carried it daily. Basically, if I am dressed, I am wearing it in a holster. I have fired hundreds of rounds each of .40 S&W, 357 SIG, and 9mm through the pistol and have lent it to students who have used it hard in multi-day shooting courses. I first carried it in a Kydex holster for about a year, then in a couple leather holsters since then. I have used it to test other holsters. I don’t baby the pistol, and in fact, there are many times that I crawl under a vehicle or something and hear it grating against the pavement. I would say that this pistol sees a lot more abuse than the average CCW pistol, but less than a military issue pistol riding in a thigh holster in combat. Here are the photos of its current condition:

Left side of the pistol after five years. Notice the edges of the controls are showing some bare steel from holster wear. The corners of the slide and rear sight show both wear and chipping from being beaten around in use and training courses. Notice the deeply worn area on the front of the thumb-rest part of the frame. This was where a Blackhawk Serpa holster actually wore deeply into the polymer of the frame prior to finishing. Not sure why the polymer Serpa caused this kind of damage, while it seems that Kydex® holsters do not.

Notice that the tan, which is a much thinner coat than the black base coat, is only slightly starting to wear along the sharp corner of the textured area of the grip in Old Bill’s guidon and the tail of his horse. The corner of the slide has been chipped to metal from being banged around.

The right side of the XD. You can clearly see holster wear on the front and corners of the slide. You can also the the gouges on the frame where the Blackhawk Serpa holster wore into the frame prior to finishing.

Notice the corners of the slide and rear sight – I beat this part of the pistol against stuff all the time when carrying it. Though it is hard to see in the photo, the right edges of the rear sight are actually peened over from being battered on stuff that I run it into. The DuraCoat chipped off of this corner of the slide and rear sight within about a year as the result of banging against rock drills when I was working on them. The corners of the ejection port show holster wear through the tan to the black, with the very corners worn to steel. Surprisingly, the sharp edges under the tan sabers have not worn through to black at all.

In this photo, which has poor focus, you can still see where the DuraCoat was chipped to bare steel from being banged into steel equipment. When it was first chipped, it showed a spiderweb cracking pattern for a week or two, and then small segments began to fall away after repeated strikes. Notice that some areas seem to be chipped but not all the way to metal. I think that these are not chips as much as gouges from rough pavement and gravel.

This pistol had basically no factory black finish left on the slide after six months of use by me (this does not mean that the metal was unprotected – the type of finish used on the XD still protects the metal even when it has worn to silver). After coating the pistol with DuraCoat and carrying and using it daily for five years, the pistol shows very little wear. No traditional finish would have survived this well.

Combat Use

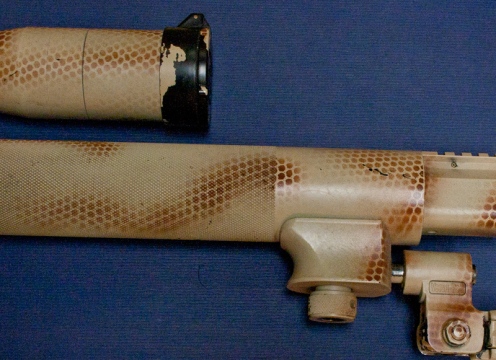

The second firearm we will look at is an SPR type rifle that I used for a year in Iraq. This weapon was not prepped prior to being coated. I just wiped the oil and dust off with a rag and sprayed it. I expected to need to re-coat the rifle several times while I was in Iraq, but the finish held up so well that I was amazed. This was my first experience with DuraCoat and to say that I was impressed is an understatement. This rifle spent a year being carried on the streets of Iraq, banging around in vehicles, and being drug through buildings and houses. By the time I left Iraq with that rifle, all the high areas of the lower receiver (which was not coated) were worn to bright aluminum, and silver was showing in the larger flat areas as well (the receiver on the rifle now is a new one) The photos speak for themselves:

The handguard shows some dings and scratches with black anodizing showing through, as well as a rub mark in the knurling where it sometimes rubbed against my gear. The front of magazine is shows chips and scratches with the remains of the original teflon coating showing gold. The corners of the scope rings show bare steel from abrasion against gear. Lower receiver is new and was not in combat.

Rear and bottom edges of the upper receiver show chipping where oil prevented good adhesion. Also, this upper was switched out with an M4 upper on occasion for certain missions, so the bottom edges of the receiver vulnerable, as it was carried in a bag in a vehicle during these times. Edges of the charging handle latch look black in the photo but are worn to aluminum. Butler Creek flip-up scope covers are rubber and flexible plastic and don’t hold a finish.

Magazines have it rough. This one was carried in the rifle at almost all times outside the wire, and in my pocket on the FOB. It shows different wear than some of my other magazines that spent more time in pouches.

On the right side, you can clearly see the thinning of the finish from being rubbed by my gloves. The areas that were handled the most all show this thinning from the abrasion of the dust on my gloves. Finish on the brass deflector chipped from being struck by ejecting brass within a day or two of being coated. You can see where the ejection port cover hits the lower reciever. While it looks black in the photo, the finish here is worn through both the DuraCoat and the parkerizing.

Rear of the right side – the high edges all show chips, scratches, and abrasion, but most damage is from impacts and scratches. The edges of the scope rings are worn more than the photo shows (to silver on the sharp corners) and the ejection port cover pin lost all of the finish that was on it. I have no idea why, probably from oil on it when coated.

More scratches on the front of the handguard tube and the Butler Creek covers hold little finish, of course. Bipod spigot has almost no finish left, while the edges where the bipod mounts and the areas where it moves are worn to bare metal and beyond to the point that it is loose and can’t really be tightened any more. This is from use and movement and vibration with sand in between the metal surfaces. It is hard to see here, but the first shots after finishing blew the DuraCoat away from the area around the gas tube roll pin where oil prevented good adhesion. It was only a bit on this side, the the other side lost a bigger chip.

Not a great photo – I somehow changed my camera settings on this shot and the light was wrong. There is quite a lot of scratches and wear on the bipod, more than this photo would make you believe. Also, the edges of the muzzle have a lot of stainless steel showing through. This photo makes it look much better than it is. The edges of the crown at the bore are chipped where the DuraCoat was blown off with the first shot, due again to lack of prep before coating.

As you can see, the DuraCoat finish on this rifle held up incredibly well. If you had seen what this rifle has been through, you would be as impressed as I am. This rifle easily saw between 400 and 500 combat missions. This was the first firearm I coated with DuraCoat, and it is what convinced me that DuraCoat is among the best firearm finishes available. Lauer Custom Weaponry, the manufacturer of DuraCoat, went far out of their way to help me out as I was headed to Iraq with this rifle, and convinced me that they are a company worth dealing with.

While all finishes will wear eventually, if the weapon is used, I think these photos of real weapons with real-world use will tell you more about what to expect from a DuraCoat finish in terms of durability than any results of various lab tests.

Thank you for the pictures and reviews of this product. I’ve used this product before. I’m a retired police officer. I wasn’t sure of the durability. I want to refinish my Smith and Wesson M&P I carried on duty. You’ve sold me on this product.

LikeLike